Our other sites:

Environmental noise is becoming an increasingly invasive part of every day life, fuelled by a growing population, housing and the infrastructure to support it all conspiring to bring people and noise sources in closer proximity. Combined with the growth of online shopping, 24-hour shopping and home deliveries, the number of hours we can expect noise intrusion has never been higher. Environmental noise pollution has been linked with chronic stress, hearing damage, hypertension, diabetes and even heart problems. The World Health Organisation (WHO) reports that noise is the second largest environmental cause of health problems.

The Importance of Noise Barriers

Noise barriers are designed to reflect or absorb sound, reducing the impact of environmental noise; for example, on developments around schools, shopping facilities, commercial premises and busy transport infrastructure.

According to the Chief Medical Officer, the level at which detrimental human health effects become evident is 55 decibels, while WHO guidelines for night noise recommend less than 40 decibels to prevent adverse health effects. Acoustic barriers are usually required on projects where there is a requirement for a minimum noise reduction of 10 decibels. Quality acoustic fencing, such as our Jakoustic® barriers, can reduce noise pollution by up to 32 decibels*.

How Acoustic Barriers Work

Understanding the properties and characteristics of noise barriers is straightforward. There are different types of noise barriers and, it’s impossible to say which one is best suited to a site without a site assessment by a qualified, independent acoustician.

Noise barriers force sound waves to take a longer path over and around the wall, which reduces the amount of sound reaching the receiver. This is called diffraction, and greater angles of diffraction result in more noise reduction.

The effectiveness of any acoustic barrier is dependent on a number of key factors:

Taking these factors into consideration, no two projects will achieve the same quality and level of noise reduction using the same acoustic product.

Reflective and Absorptive Acoustic Barriers

There are two types of timber acoustic barriers that deal with unwanted noise: reflective and absorptive.

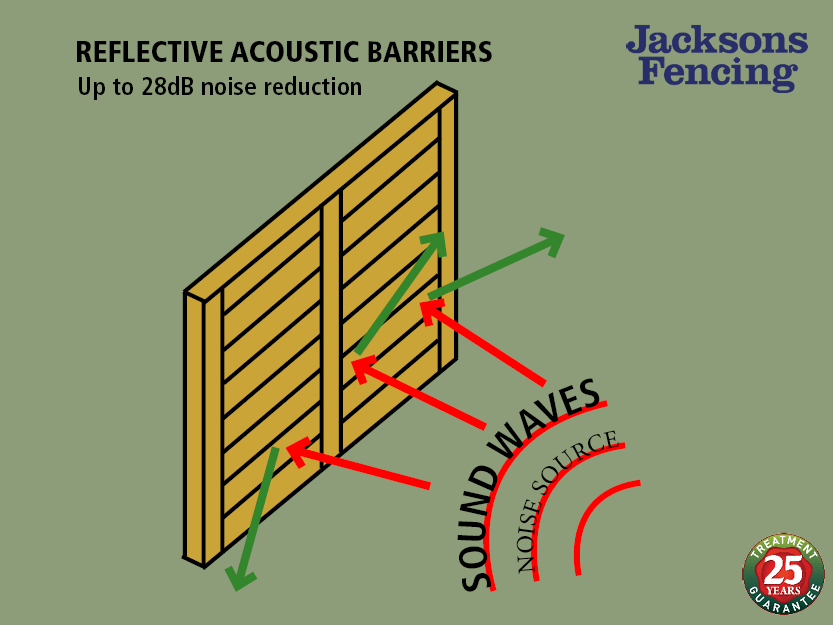

Reflective Acoustic Barriers

By default, a noise barrier without any added absorptive treatment is reflective. Reflective barriers are the most commonly used type, where sound waves meet the barrier and are redirected away from the protected area. For example, in motorway applications a reflective noise barrier on one side can reflect sound energy away from the protected area. Reflective barriers are widely regarded as a straightforward and highly effective noise reduction solution. Using Jacksons’ reflective acoustic barriers as an example, they feature:

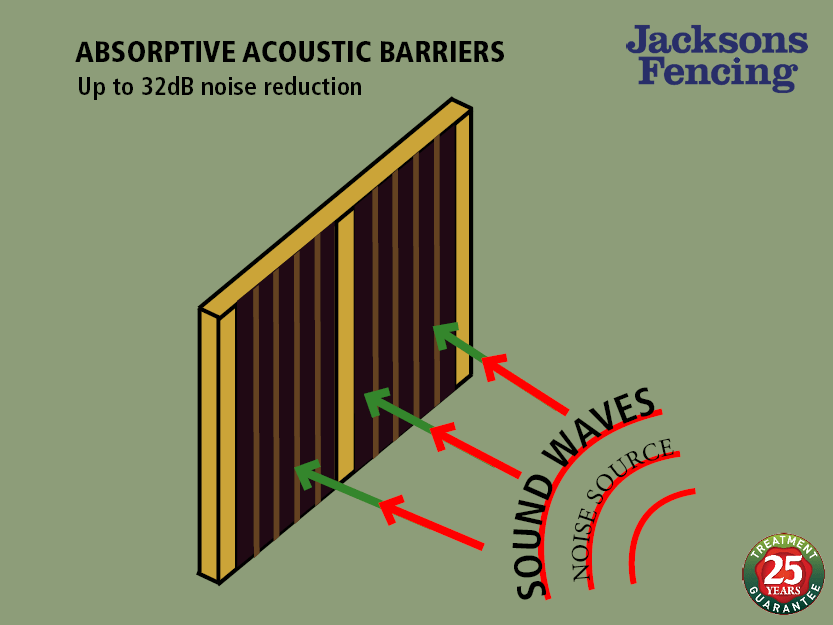

Absorptive Acoustic Barriers

For noise issues within a confined space where reflective barriers are unsuitable, an absorptive barrier is the best solution as it traps and breaks down sound frequency, diffusing sound waves completely, rather than reflecting it in a different direction. For example, two parallel reflective barriers could, in some settings, increase noise levels in the space between them as the sound energy ricochets off each fence. Here, absorptive barriers would eliminate the sound waves, overcoming any chance of reverberation. Using Jacksons’ absorptive acoustic barriers as an example, they feature:

It cannot be said which type of sound barrier is better: reflective and absorptive barriers are suitable for different sites and their individual needs. We recommend a qualified sound engineer is consulted prior to a product being specified; a professional acoustician can provide a detailed report to help you make an informed decision. We have a list of independent sound engineers that cover the country—please contact us for details of an engineer in your area or to initially discuss your requirements.

*Jakoustic® Plus Absorptive Layer barrier certified laboratory results: Category B3 rating according to BS EN 1793-2:1998 Category A3 rating according to BS EN 1793-1:1998 Laboratory sound reduction 32 dB Approximate Superficial Mass 28kg/m²

Related products

Jacksons Security has a range of products relating to this article, all complete with our 25 year service life guarantee. If you cannot find the item you are looking for, please do not hesitate to call our friendly sales team.

Related Content

Top