Our other sites:

A critical aspect of a robust, long-lasting fence is its finish. Coating the product in the right way and with the appropriate care is an essential part of the fence-manufacturing process, improving the overall appearance of the fence and, therefore, the site. A coating is also important in allowing clients to match colour schemes (such as their brand colours) and creates a smooth surface while prolonging the life of the fence. The pre-treatment, application and quality management of finishes should conform to high industry standards to ensure a tough, durable exterior; products with comprehensive guarantees will indicate that the fence has been finished with care.

Before any product is coated, it is hand-fettled to remove any imperfections and inspected to ensure the fence will drain thoroughly , allowing a smooth finish. Budget, environment and location will influence which finish will be best suited for the requirements of your site.

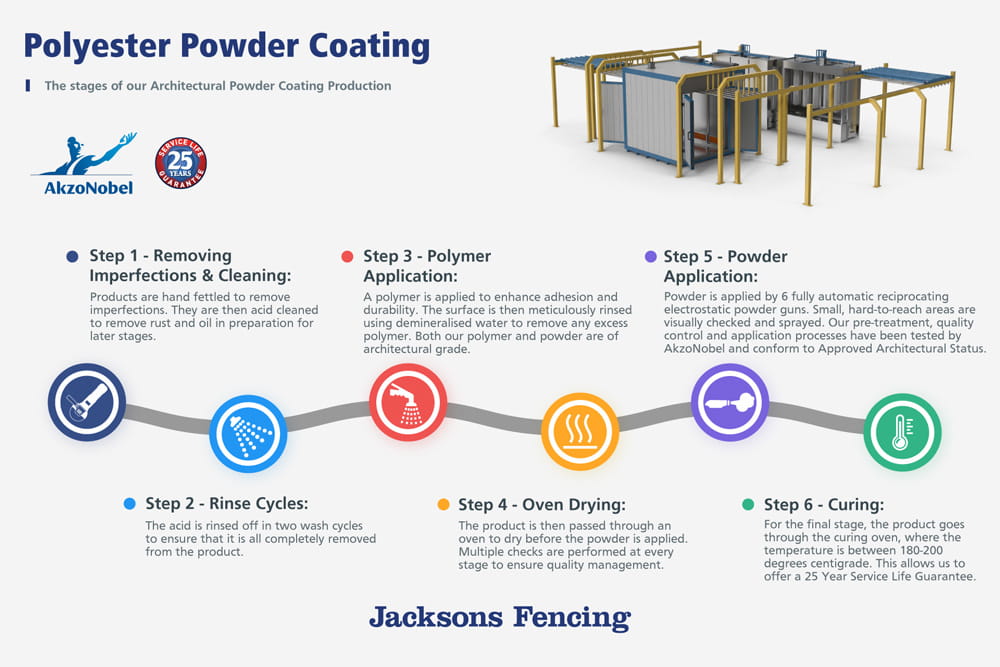

Powder Coating

Essentially, powder coating is paint in powder form which is positively charged to ensure that it’s attracted to the surface of the product. After the fence has been cleansed by acid, powder coating is applied using compressed air and the product goes through a curing oven . The powder then forms a skin that cools into a hard finish. Powder coating delivers a thicker coating than traditional paints, without any running or dripping. Along with being visually attractive, the finish is high performing and durable. Powder coating has excellent colour and gloss retention – ideal for fences that are frequently exposed to the sun and harsh weather. It's also very quick to apply in comparison to painting; however, powder coat is not available for timber fences as the paint needs to be heated to cure it, so timber products need to be painted by hand.

Marine Finish

Our Marine Finish is resistant to stress-cracking, detergents, adverse weather conditions, salt spray and typical airborne pollutants, as well as being suitable for in-water contact. It is specifically designed to provide a long-lasting and durable coating, with a good degree of electrical insulation and impact resistance too. A marine finish will prolong the lifespan of any fence and is particularly suitable when the barrier is installed in challenging environments. These include: swimming pools, since marine coating is resistant to the fumes from chlorinated pools; playgrounds, as the finish can withstand rigorous activity; and, of course, offshore marine sites, where it can endure high-impact waves.

Galvanised Finish

Rust and corrosion prevention should be a key factor when choosing a fence. One of the best ways of protecting against corrosion is hot-dip galvanisation: a process in which the entire fence surface is dipped into molten zinc, coating it completely. This provides a barrier of protection between the metal and its surrounding environment. It is highly effective in preserving fences because the corrosion of zinc, which protects the base metal, is very slow; a zinc coating therefore provides ‘sacrificial protection’.

The Galfan® Finish

This exceptional finish is available as standard with our welded security mesh panels and extends the life of the coating by up to four times longer than galvanised products. Comprising 95% zinc and 5% aluminium, the zinc actively works as a sacrificial anode. The aluminium, as it oxidises, forms a graphite-coloured protective layer on the surface which inhibits the anodic reaction of the zinc.

The Galfan® Finish demonstrates a better quality-to-price ratio, which enables it to replace conventional galvanised wiring and offer the end user economical benefits . As it creates a thinner layer, Galfan® coating improves weldability. This means that more detail can be created, such as small apertures in mesh panels, which is why Jacksons Fencing chooses it for our welded mesh fences.

All steel fencing and gate designs from Jacksons Fencing are supplied galvanised to BS EN 1461 as standard, or galvanised and powder-coated to BS EN 13438 in one of our standard colours at an additional cost.

Related products

Jacksons Security has a range of products relating to this article, all complete with our 25 year service life guarantee. If you cannot find the item you are looking for, please do not hesitate to call our friendly sales team.

Related Content

Top