Our other sites:

Sliding Gates

Sliding gates operate with either a cantilever or tracked system, where the gate leaf or leaves slide to open and close. Sliding gates are ideal for applications where a swinging motion is not practical, or enhanced security is required. They also provide improved strength against wind loading, and reduced wear and tear on hinges over time, when compared to swing gates. Our sliding gates are available with manual or automated operation.

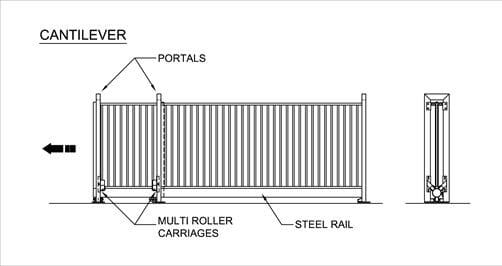

Cantilever Sliding Gates

Cantilever sliding gates are designed to glide effortlessly without the need for a ground track. Their counterbalanced design allows them to hover above the ground, making them ideal for uneven surfaces, driveways with slopes, or areas where debris might obstruct a tracked system.

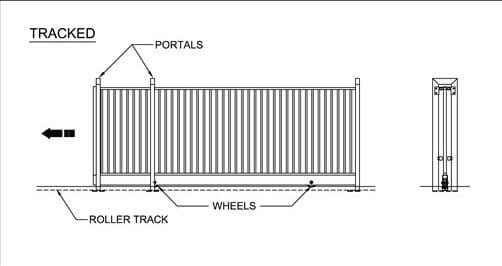

Tracked Sliding Gates

Tracked sliding gates run along a fixed rail embedded into level ground, providing a stable and reliable solution for securing larger entrances. This system allows for increased weight capacity, making it perfect for heavy-duty industrial or commercial applications.

Automated Sliding Gates

All our automated sliding gates are UKCA/CE marked in compliance with the Supply of Machinery (Safety) Regulations 2008. We offer professional installation and automation, carried out by our DHF Level 2 trained engineers, with a 25-month automation guarantee for peace of mind.

Contact Us

Vertical Bar Sliding Gates

A perfect match to our vertical bar railings, vertical bar sliding gates are available in any style including the Barbican® range, Sentry® and Tri-Guard®. Vertical bar sliding gates are our most popular type of sliding gate due to their smart appearance and durability. Constructed from tubular steel and with welded pale-through-rail construction, vertical bar sliding gates are strong and secure, yet lightweight. Available as tracked or cantilever gates, in double or single leaf configuration.

Welded Mesh Sliding Gates

Designed for security and visibility, our mesh sliding gates provide a robust, lightweight. cost effective gate solution. Matching our mesh fencing systems, these gates are available in a range of styles, including our EuroGuard twin wire and v mesh, and 358 prison mesh styles. Constructed from premium welded mesh panels and reinforced with a steel frame, our mesh sliding gates offer excellent durability while maintaining airflow and sightlines. Available in tracked or cantilever configurations, with single or double leaf options.

Acoustic Sliding Gates

Combining a natural timber aesthetic with good security due to their anti-climb flat profile, our acoustic sliding gates are designed to reduce noise while perfectly complementing our acoustic barrier systems in both appearances and performance. Acoustic sliding gates are ideal for environments where both security, privacy, and sound reduction are essential, such as industrial sites, transport hubs, and residential developments. Constructed with heavy-duty steel frames and high-density timber infill, our acoustic sliding gates offer superior strength and long-lasting durability. Available in tracked or cantilever configurations*, with single or double leaf options.

Cantilever Sliding Gates

A cantilever gate is counterbalanced and does not require a track to run along the opening. The gate is supported by rollers which slide in a tubular track which is fitted to the bottom of the gate.

Available in either a single or double leaf configuration, along with the option of being manual or automated gates.

Infill Options

- Welded Mesh (EuroGuard, Securi Mesh)

- Railings (Barbican, Sentry, TriGuard, Defender, Imperial, Ornamental, Barbican Extra, Bow Top)

- Timber - Acoustic or Tongue and Groove

Tracked Sliding Gates

Tracked sliding gates run along a track which is installed along the opening. The gate is guided along the track with wheels at the base of the gate.

In order for the gate to work efficiently the track needs to remain clear from debris

Infill Options

- Welded Mesh (EuroGuard, Securi Mesh)

- Railings (Barbican, Sentry, TriGuard, Defender, Imperial, Ornamental, Barbican Extra, Bow Top)

- Timber - Acoustic or Tongue and Groove

Electric Sliding Gates

Sliding gates can be operated manually, but are generally automated for ease of use and convenience, particularly larger gates. Find out more about the features and technical details of our electric sliding gates.

Electric Sliding GatesTimber Sliding Gates

Commonly seen in residential properties or gated estates, our timber sliding gates have a solid boarded tongue and groove effect infill which increases privacy, and can operate with a track or cantilever mechanism and range of access control devices. All timber is premium quality pressure treated and guaranteed for 25 years, with an additional 25 month automation guarantee.

Timber Sliding GatesAdvantages of sliding gates

Limited Space

Sliding gates are ideal for providing access to sites where space in front of the gate is tight, such as short driveways or forecourts, enclosures with lots of equipment or machinery to fit in, or if other access control measures are in place too, like bollards or traffic barriers. Unlike swing gates, sliding gates slide parallel to the fence line, requiring minimal space in front and behind the fence. They need space to the side of the gate to slide into.

Enhanced security

Sliding gates provide operational efficiency, with quick open and close cycles. Their rapid movement allows for fast entry for vehicles, reducing the time that gates remain open and thus minimising security risks. Structural integrity is also improved: typically constructed as a single, solid panel, their design is difficult to force open because the gate is anchored at both ends when closed, offering minimal leverage points.

Maintenance requirements

Sliding gates generally see fewer problems than swing gates, due to less mechanical stress on hinges and moving parts, as long as the tracks of sliding gates are kept clear, and wheels are in good condition. Swing gates have hinges that bear the weight, and are also more affected by wind forces, subjecting them to more wear and tear, sagging and adjustments. Motors also need more mechanical force for swing gates and therefore more maintenance.

Can the weather impact sliding gates?

Automation equipment can operate in extreme heat and extreme cold, as long as it is regularly maintained and kept in good condition. The structure of the sliding gate will not directly be impacted by the weather, however side effects such as fallen leaves and debris from strong wind, snow, and ice can impact tracked gates; requiring the track to be cleared, but cantilever gates will remain unaffected.

Do sliding gates take up more space?

A sliding gate needs more space to the sides of the opening, while a swing gate needs more space directly in front, where the gate leaves will swing into. A sliding gate leaf must be able to slide either side of the opening rather than opening into the space in front or behind the gate. Sliding gates are often used where space is limited just in front of a gate, such as a short driveway or forecourt. A swing gate will need space in front and behind the opening, but a sliding gate can run neatly parallel to a fence line.

Where are sliding gates often used?

Sliding gates are often used in commercial settings where there is high traffic flow. The quick operation time of a sliding gate increases security by quickly closing the gap between letting in vehicles.

Related Products

Our gates come with a 25 year guarantee and a 25 month automation guarantee. Browse our other products relating to gates and gate automation. If you cannot find the item you are looking for, please contact us.

Document Downloads

Download specification documents, drawings and case studies for this product

Top